Crude oil is a vital natural resource that plays a crucial role in the global economy. It serves as the primary source for various fuels, lubricants, and other products we rely on daily. However, crude oil cannot be used in its raw form. To convert it into usable products, it must undergo a complex process called refining. In this article, we will explore what refining crude oil means, the steps involved in the refining process, and its importance to our lives and the economy.

Understanding Crude Oil

Before diving into the refining process, it’s essential to understand what crude oil is. Crude oil is a thick, black liquid found deep beneath the Earth’s surface. It is made up of a mixture of hydrocarbons, which are organic compounds consisting of hydrogen and carbon. Crude oil is extracted from the ground through drilling and is often referred to as “black gold” due to its value in the energy market.

The Importance of Refining Crude Oil

Refining crude oil is necessary because it transforms this raw material into usable products. These products include gasoline, diesel fuel, jet fuel, heating oil, and various petrochemicals used in making plastics and other materials. The refining process helps ensure a reliable supply of energy and raw materials for countless industries and consumers worldwide.

Refining also contributes to the economy by creating jobs and supporting related industries, such as transportation and manufacturing. Without refining, the vast reserves of crude oil would remain largely untapped and unproductive.

The Refining Process

The refining process involves several steps that convert crude oil into valuable products. The key stages of refining include:

- Distillation

- Conversion

- Treatment

- Blending

Let’s take a closer look at each of these steps.

See also: How Long Does It Take to Process Crude Oil into Gasoline?

1. Distillation

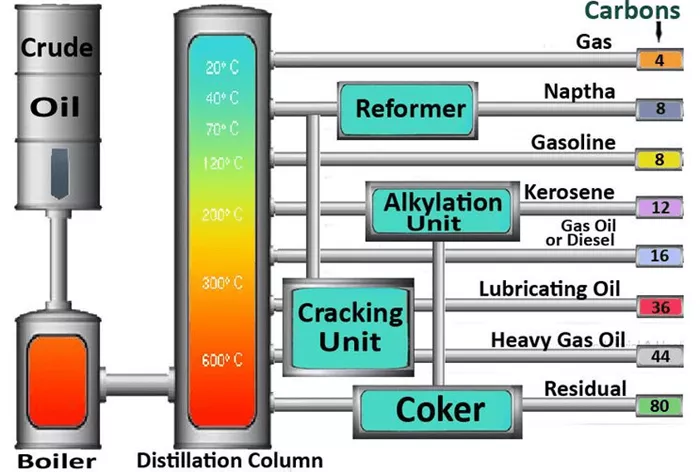

The first step in refining crude oil is distillation. This process separates crude oil into different components based on their boiling points. Here’s how it works:

Heating: Crude oil is heated in a distillation column. As it heats up, it vaporizes.

Separation: The vapor rises through the column and cools down. As it cools, different hydrocarbons condense back into liquid at various heights in the column. The lighter components, such as gasoline, condense at the top, while heavier components, such as asphalt, condense at the bottom.

Distillation is essential because it allows refineries to separate crude oil into its various fractions, which can be further processed to create different products.

2. Conversion

After distillation, the next step is conversion. This stage transforms heavier fractions of crude oil into lighter, more useful products. There are two main methods of conversion:

Cracking: This process breaks down larger hydrocarbons into smaller ones. It can be done using heat (thermal cracking) or catalysts (catalytic cracking). Cracking is essential for maximizing the yield of gasoline and other light products from crude oil.

Reforming: This process alters the structure of hydrocarbons to improve the quality of gasoline. It increases the octane rating, making the fuel more efficient.

Conversion is a critical step in refining, as it helps optimize the yield of valuable products from crude oil.

3. Treatment

Once the crude oil has been distilled and converted, it undergoes treatment. This step removes impurities and enhances the quality of the final product. Treatment involves several processes, including:

Hydrotreating: This process uses hydrogen to remove sulfur and nitrogen compounds from the oil. Reducing these impurities is vital for meeting environmental regulations and ensuring the gasoline burns cleanly.

Desulfurization: Similar to hydrotreating, this step further reduces sulfur content. Lower sulfur levels help minimize air pollution when the gasoline is burned.

Treatment processes can vary in duration depending on the initial quality of the crude oil and the specifications of the final product.

4. Blending

The final step in refining crude oil is blending. In this stage, various petroleum products are mixed to create the final gasoline product that meets specific performance and regulatory standards. Blending includes:

Combining different gasoline streams: Refiners often mix various gasoline fractions to achieve the desired octane rating and volatility.

Adding additives: Additives are included to enhance performance, prevent engine knocking, and improve fuel stability.

Blending typically takes a few hours, depending on the complexity of the formulation and the desired product characteristics.

See also: When to Invest in Crude Oil?

The Overall Refining Timeline

The time it takes to refine crude oil into usable products can vary. Generally, the entire process can take anywhere from a few days to a week. Here’s a rough breakdown of the timeline:

Distillation: A few hours

Conversion: Several hours to a few days

Treatment: Several hours

Blending: A few hours

This timeline can be influenced by factors such as the type of crude oil being processed, the refinery’s capacity, and technological advancements.

Key Products of Crude Oil Refining

The refining process produces a variety of products that are essential to modern life. Some of the primary products derived from crude oil refining include:

Gasoline: Used to power vehicles, gasoline is one of the most widely consumed petroleum products. It is essential for transportation and is a critical part of the economy.

Diesel Fuel: Diesel is used in trucks, buses, and heavy machinery. It is vital for freight transportation and many industrial applications.

Jet Fuel: This specialized fuel powers commercial and military aircraft. The aviation industry relies heavily on jet fuel for efficient air travel.

Heating Oil: Used for residential and commercial heating, heating oil is especially important in colder climates.

Petrochemicals: These are the building blocks for various products, including plastics, fertilizers, and synthetic fibers. Petrochemicals play a significant role in multiple industries.

Environmental Considerations in Refining

While refining crude oil is essential for producing valuable products, it also poses environmental challenges. The refining process can result in emissions, waste, and pollution. Here are some key environmental considerations:

Air Pollution: Refineries emit pollutants, including sulfur dioxide, nitrogen oxides, and volatile organic compounds. These emissions can contribute to air quality issues and health problems in surrounding communities.

Water Pollution: Refineries use water for cooling and processing, which can lead to wastewater discharge. If not properly managed, this wastewater can contaminate local water sources.

Greenhouse Gas Emissions: The refining process generates greenhouse gases, contributing to climate change. As global concerns about climate change increase, the industry is under pressure to reduce its carbon footprint.

Waste Management: Refineries generate various waste products, including sludge and spent catalysts. Proper waste management practices are essential to minimize environmental impact.

To address these challenges, the refining industry is investing in cleaner technologies and practices. This includes improving energy efficiency, reducing emissions, and implementing better waste management systems.

The Future of Crude Oil Refining

As the world moves towards sustainability and renewable energy, the future of crude oil refining is likely to evolve. Here are some trends and considerations for the refining industry:

Transition to Renewable Fuels: The demand for renewable fuels, such as biofuels and hydrogen, is increasing. Some refineries are adapting to produce these alternative fuels, diversifying their product offerings.

Technological Innovation: Advances in refining technology can lead to more efficient processes and reduced environmental impacts. Innovations such as carbon capture and storage (CCS) may help mitigate emissions associated with refining.

Market Dynamics: The global oil market is influenced by geopolitical factors, supply chain disruptions, and changes in consumer behavior. As electric vehicles become more prevalent, the demand for traditional gasoline may decline, prompting refineries to adapt to shifting market dynamics.

Environmental Regulations: As governments implement stricter environmental regulations, refineries will need to invest in cleaner technologies. Compliance with these regulations may require changes to existing refining processes, potentially impacting costs and timelines.

Circular Economy: The concept of a circular economy encourages the recycling and repurposing of materials. Refineries may explore ways to integrate circular economy principles into their operations, reducing waste and improving resource efficiency.

Conclusion

Refining crude oil is a complex and essential process that transforms raw crude oil into valuable products. Through distillation, conversion, treatment, and blending, refineries produce gasoline, diesel, jet fuel, and many other essential products. The refining industry plays a crucial role in the economy by providing energy and raw materials for various industries. However, refining also poses environmental challenges that must be addressed. As the world shifts towards sustainability, the refining industry will need to adapt to changing market dynamics and regulatory pressures. By investing in cleaner technologies and practices, the industry can continue to meet the growing demand for energy while minimizing its environmental impact.

Related Topics: